Pistons

Performance Forge, Inc. has been producing high quality, forged aluminum pistons from Day One! The very first part we hit in 1995, when the company was started, was a forged aluminum piston!

high quality - high precision - high performance

Our roots in forged pistons actually go even deeper than our first part in 1995. Several of us were employees of Alcoa – Vernon before their shutdown, and we were forging aluminum pistons at that facility for years. So our experience actually goes back into the 1970’s and 80’s!

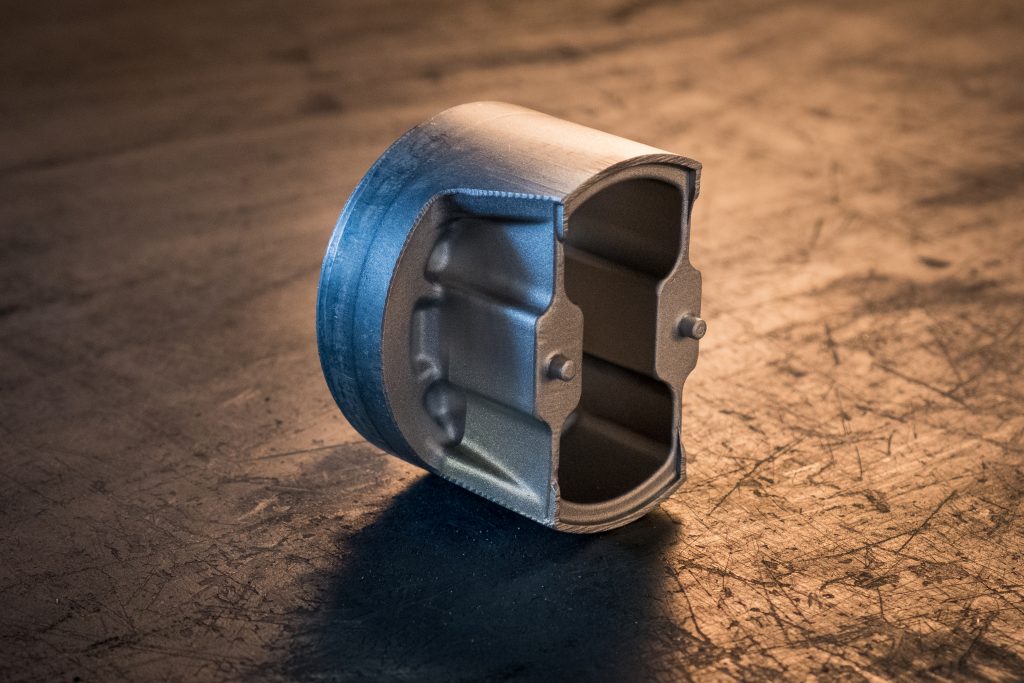

We have seen piston design and technology evolve over the years, from the early days of a simple “can-style” piston, to the more exotic styles of today, with forged side reliefs, cross ribs, wrist pin tower gussets, short and thin skirts, and thin struts.

At Performance Forge, we pioneered the process of making these complex piston designs on a mechanical forge press. Using a mechanical press ensures optimal grain structure, by producing the smallest grain size and tightest grain structure. This pioneering process was not easy or cheap, but…

“when you want it done right and only the best process will do,

you just have to figure out a way to get it done…and we did!”

Additionally, as any metallurgist will tell you, the longer a piece of aluminum is exposed to heat, the larger the grains become. They will also tell you that a small, tight grain structure produces the strongest parts. So, in addition to using a mechanical forge press to produce these tight grains, Performance Forge also invested in superior heating technology that can bring the billet stock to temperature quickly. Traditional technology would require the billet aluminum to be exposed to heat in an oven for two hours before achieving forge temperature. This new heating technology can heat a billet piece of aluminum from room temperature, to over 800°F, in less than 20 minutes.

Whether you want your pistons in 2618-T61 or 4032-T6, we can accommodate that for you. We typically carry a complete inventory of stock sizes to make just about whatever you need in a very short lead-time.

Here are just some of the things we offer:

- Minimum Order Quantities of only 250 pieces

- Made from Aircraft Grade Aluminum: 2618-T61 or 4032-T6

- Tight Dimensional Tolerances, usually +0.020” / – 0.010”

- All non-machined surfaces are shot peened

- Pre-turn option is available

We can handle your most difficult Piston Project. Just send us a note from our “Contact Us” Page, or to Sales@Performance-Forge.com, and we will assign our best engineers to your project!